6-20 個字符(僅限字母加數字)

密碼不一致

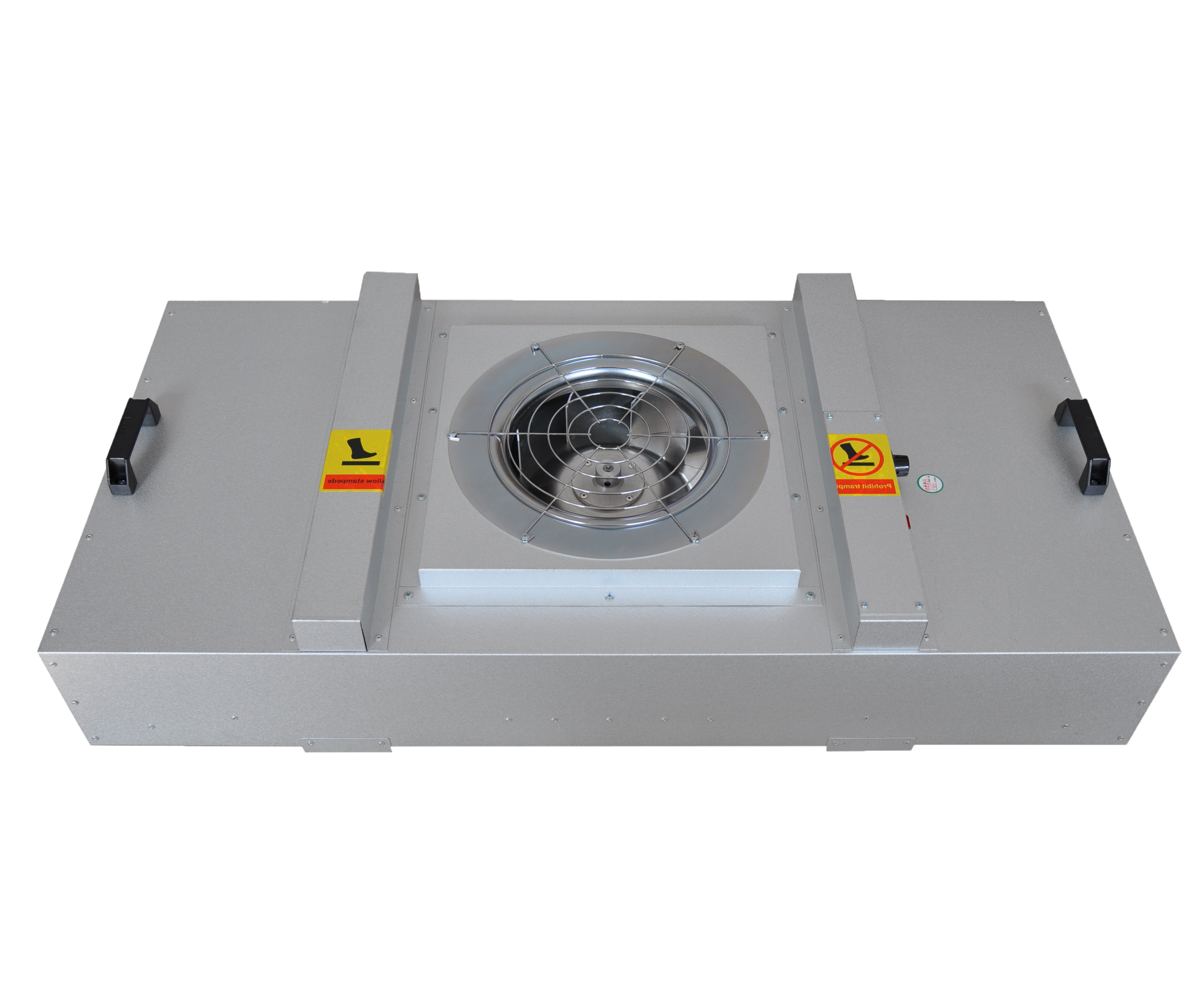

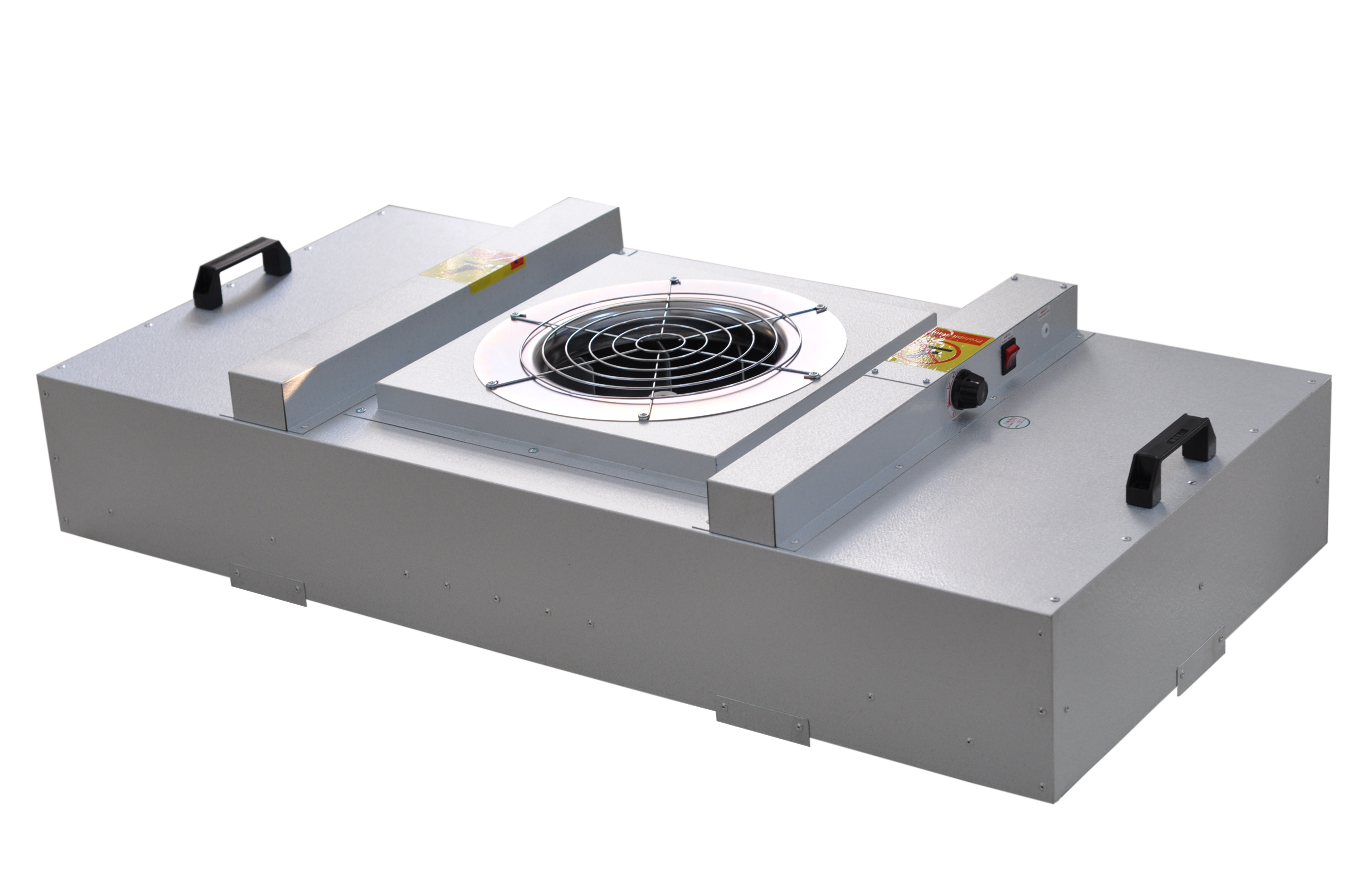

FFU(風扇過濾器單元)

Deshengxin的FFU(風扇濾清器單元)是一個重要元素,旨在在空氣質量至關重要的關鍵情況下使用。我們的FFU既可以為過濾和效率提供最高水平的清潔和效率,在確保空氣具有高質量方面起著至關重要的作用。通過強大風扇的力量與現代過濾系統的功能,我們的FFU有效地消除了空氣中的污染物和灰塵。這創造了一個乾淨的環境,對於不同行業來說是必不可少的,包括半導體製造和醫療機構,實驗室和潔淨室。我們相信我們的FFU可以為您的關鍵活動提供高質量的性能和毫不妥協的空氣質量。

The company's FFU (Fan Filter Unit) is an essential part specifically designed for use in environments where the highest quality of air is of paramount importance. With its modern technology and dependable performance the FFU is an essential component in ensuring that the air inside cleanrooms and controlled areas is not just clean but is also properly filtered to ensure that it meets strict standards for cleanliness.

Principal characteristics of DSX FFU include:

1. High-Efficiency Filtration Our FFU is fitted with top-quality filters that efficiently eliminate particles, contaminants, and airborne pathogens from air, ensuring a healthy and safe environment for delicate equipment and processes.

2. energy efficiency: The Hepa fan filter is engineered to run efficiently, with minimal power consumption and a smooth operation. This makes it a green and cost-effective option for cleanrooms.

3. Adjustable AirflowThe flow of air in our FFU is easily adjustable to meet airflow requirements specific to the area to ensure the best air distribution and hygiene levels within the cleanroom.

4. easy installation and maintenanceDeshengxin FFU is engineered for ease of installation and maintenance using user-friendly features that facilitate rapid replacement of filters and maintenance which reduces downtime while ensuring the continuous operation.

5. Strong ConstructionBuilt using high-quality components Our FFU is long-lasting and durable and reliable in the most demanding cleanroom environments.

6. Full Chain of Industry Production Through monitoring all stages of production from raw materials through finished items, Deshengxin ensures quality control throughout the entire process leading to superior quality products and superior performance.

7. Fast delivery: With efficient production procedures and a well-managed logistics chain DSX offers competitive lead time, and guarantee the timely delivery of FFUs to meet the needs of customers and deadlines for projects.

8. Price Competitive:Our integrated production process throughout the entire chain of industry lets us offer highly competitive prices. Through coordinating every step of production in-house, we can optimize cost and efficiency, offering our customers cost-effective solutions without sacrificing quality. This helps us offer exceptional value in the marketplace, while ensuring that our products are affordable while achieving the most stringent standards of quality and performance.

Deshengxin FFU is a versatile and efficient method of maintaining quality air in the most critical areas like cleanrooms, laboratories and healthcare facilities. Customers benefit not only from the latest technology and efficiency that comes with the FFU but as well from the security of an integrated solution that can address their air filtration requirements in depth. Contact us today to find out more about the ways our FFU can improve the efficiency and cleanliness of your air filtering system.

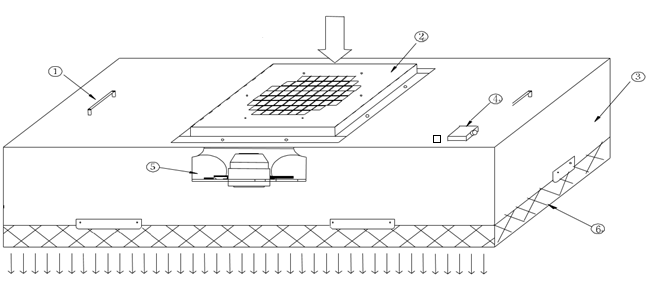

FFU Assembly diagram

|

1 |

|

5 |

Motor |

|

2 |

|

6 |

HEPA filter |

|

3 |

|

|

|

|

4 |

|

|

|

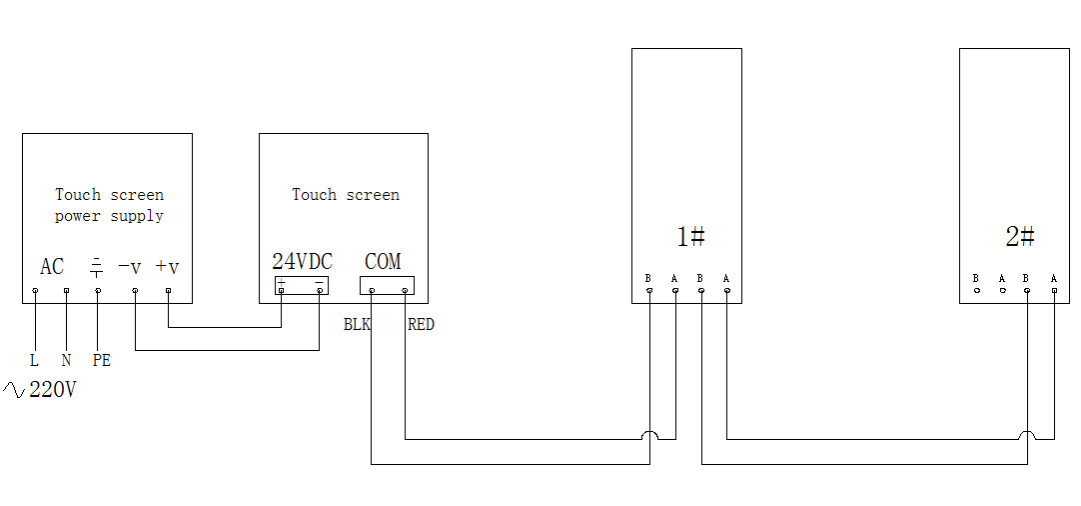

FFU Wiring diagram (Group control)

DSX FFU Introduction

Versatile FFU Systems with Customizable Materials, Motors, and Controls

Materials for ontology that can be used as an option such as steel plate paint stainless steel 304, 316 Aluminum plate Optional several efficient AC/DC motorsIndividually controlled and centrally via a computer network. It can also be monitored remotely

Filters are made from fiberglass, PTFE, or are available using HEPA, ULPA filters of various levels of filtration.

Effective and quiet FFU Systems that are Space-Saving Design and a Stable Airflow.

DSX FFU uses an easy and light design which saves space and facilitates installation and maintenance.The particular design of the air intake and air conduit layout reduces noise, vibration, and noise production.

The internal diffuser plate provides an even air pressure distribution and stability of wind speed at the outlet.

Customizable FFU Systems with Energy-Efficient Motors

It is powered by a high-efficiency motor that can be adjusted to three speeds and low power consumption and low operating expenses (DC motors are also chosen to save energy). The motor was developed and manufactured by DSX and is able to be adjusted in accordance with the needs of the customer.

Versatile FFU Systems with Multiple Filter Options for Superior Filtration

Filter materials could be fiberglass, PTFE or optional HEPA and ULPA filtering systems with various filtering levels. Filter grade options include H13, U14 U15 and U16.

Perfect for special events

In addition to FFUs that are used in normal situations, we also offer FFUs that are specifically designed for industries that use lithium batteries, extremely thin FFUs for spaces with limited space, and explosion-proof FFUs. As a leading FFU producer, we are able to customize FFUs to suit various situations for our customers.

Make sure you are in a clean area

Each of DSX FFUs is assembled in cleanrooms to guarantee an extremely clean environment. Our FFUs strictly follow the strictest guidelines and adhere to cleanroom procedures throughout the production process. This strict approach ensures we can guarantee that the FFUs are clean of any contamination, which is essential to ensure optimal performance while maintaining clean working environments across a variety of applications.

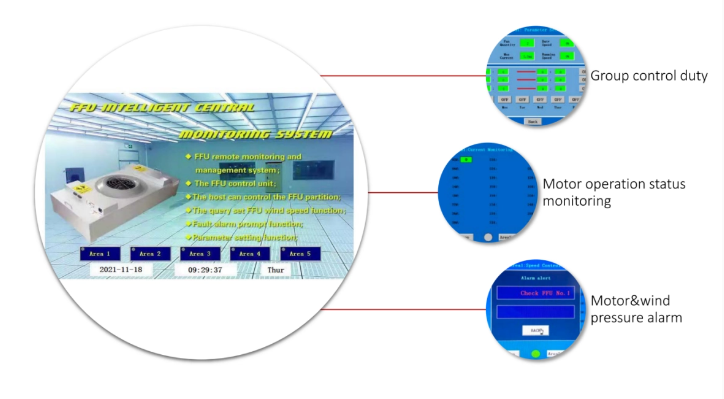

Customizable FFU Control System: Enhancing Efficiency and Performance

We have developed our FFU control system was developed and created by our own engineers, offering unparalleled flexibility and customization. With attention to particulars the control system we use offers an array of customizable options to satisfy specific customer needs. If it's creating the interface for control, altering rates of baud, or choosing the preferred option for display language Our control system is able to be customized to meet different communication styles and requirements of the customer. This flexibility allows for an easy integration into existing systems, and increases the overall effectiveness and efficiency for our FFUs.

Deshengxin FFU Regular parameters

| DESCRIPTION | Size(L*W*HMM) (Including HEPA) |

Air velocity (m3/h) |

Air flow (m/s) | Noise | Position of testing noise | Shell material | Power Supply | Rated power |

| Ultra thin FFU | 1175*575*180 | 1000 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.17kw |

| FFU575575 | 575*575*320 | 500 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.12kw |

| FFU615615 | 615*615*320 | 700 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.12kw |

| FFU915615 | 915*615*320 | 900 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.12kw |

| FFU1175575 | 1175*575*320 | 1000 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.12kw |

| FFU1175*1175 | 1175*1175*350 | 2000 | 0.45m/s (±20%) | ≤59Db | 1.2m far below the filter | Zn-Al coated plate/ stainless steel |

220v/110V | 0.18kw |

The size and other parameters can be customized according to the clients' demands.

1.FFU parameters(CE):

|

Model |

DSX-FFU01-02 |

DSX-FFU01-02 |

DSX-FFU01-03 |

DSX-FFU02-02 |

DSX-FFU02-04 |

|

FFU dimension (mm) |

575 x 575 x 210 |

1175 x 575 x 210 |

1175 x 575 x 270 |

1175 x 1175 x 270 |

1175x1175x210 |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

||||

|

Fan |

AC |

||||

|

Input |

230ACV/60HZ/1P |

||||

|

Speed (m/s) |

0.45~1 m/s±20% at high speed |

||||

|

Control type |

Manual |

||||

|

HEPA Height (mm) |

50 / 70 Optional |

||||

|

HEPA filter material |

Glass fibre |

||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||

|

Operating temperature |

10~40℃ |

||||

|

Structure type |

Split type |

||||

|

Installation mode |

Horizontal / Vertical |

||||

2. FFU parameters(Ultrathin type):

|

Model |

Ultrathin type |

|||

|

FFU dimension (mm) |

875X575X160 |

1350X460X160 |

1600X460X160 |

Other dimension |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

|||

|

Fan |

AC / EC |

|||

|

Input |

220ACV/50HZ/1P |

|||

|

Speed (m/s) |

0.45~0.7 m/s±20% at high speed |

|||

|

Control type |

Manual / RS485 |

|||

|

HEPA Height (mm) |

50 / 70 Optional |

|||

|

HEPA filter material |

Glass fibre |

|||

|

HEPA efficiency |

H13 / H14 /U15 |

|||

|

Operating temperature |

10~40℃ |

|||

|

Structure type |

Split type |

|||

|

Installation mode |

Horizontal / Vertical |

|||

3.FFU parameters(Conventional type):

|

Model |

Conventional type |

||||

|

FFU dimension (mm) |

575x575x230 |

765X510X230 |

1000X520X230 |

1175X575X230 |

Other |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

||||

|

Fan |

AC / EC |

||||

|

Input |

220ACV/50HZ/1P |

||||

|

Speed (m/s) |

0.45m/s±20% at high speed |

||||

|

Control type |

Manual / RS485 |

||||

|

HEPA Height (mm) |

50 / 70 Optional |

||||

|

HEPA filter material |

Glass fibre |

||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||

|

Operating temperature |

10~40℃ |

||||

|

Structure type |

Split type |

||||

|

Installation mode |

Horizontal / Vertical |

||||

4.FFU parameters(High speed type ):

|

Model |

High speed type |

|||

|

FFU dimension (mm) |

430X430X270 |

1175X575X270 |

1175X175X270 |

Other |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

|||

|

Fan |

AC / EC |

|||

|

Input |

220ACV/50HZ/1P |

|||

|

Speed (m/s) |

1m/s±20% at high speed |

|||

|

Control type |

Manual / RS485 |

|||

|

HEPA Height (mm) |

50 / 70 Optional |

|||

|

HEPA filter material |

Glass fibre |

|||

|

HEPA efficiency |

H13 / H14 /U15 |

|||

|

Operating temperature |

10~40℃ |

|||

|

Structure type |

Split type |

|||

|

Installation mode |

Horizontal / Vertical |

|||

5.FFU parameters(Special type ):

|

Model |

F-DA190X1-SUS304-400X400X100-F50H13 |

F-DA190X1-SUS304-430X430X120-F70H13 |

|

FFU dimension (mm) |

400 X 400 X 100 |

400 X 400 X 120 |

|

FFU material |

SUS304 / SUS201 / SUS 316 / SUS430 / SGLC / Powder coated |

|

|

Fan |

AC |

|

|

Input |

220ACV/50HZ/1P |

|

|

Speed (m/s) |

0.25m/s±20% at high speed |

|

|

Control type |

Manual |

|

|

HEPA Height (mm) |

50 / 70 Optional |

|

|

HEPA filter material |

Glass fibre |

|

|

HEPA efficiency |

H13 / H14 /U15 |

|

|

Operating temperature |

10~40℃ |

|

|

Structure type |

Split type |

|

|

Installation mode |

Horizontal / Vertical |

|

HEPA filter parameters

|

HEPA grade |

H13 |

H14 |

U15 |

|

HEPA eff. |

99.99%@0.3um |

99.995%@0.3um |

99.9995%@0.3um |

|

Material |

Glass fibre |

||

|

Frame material |

Aluminium alloy |

||

|

Net cover |

High quality steel baking paint (double-sided) |

||

|

Gasket |

High density synthetic rubber |

||

6.FFU parameters(3 speed type )

|

Model |

3 speed type FFU |

||||||

|

FFU dimension (mm) |

600X400 |

700X400 |

575X575 |

1175X575 |

1350X400 |

1470X400 |

Other |

|

FFU material |

Powder coated |

||||||

|

Fan |

AC |

||||||

|

Input |

220-230ACV/50HZ/1P |

||||||

|

Speed (m/s) |

0.45-1.0m/s Adjustable |

||||||

|

Control type |

Manual / RS485 |

||||||

|

HEPA Height (mm) |

50 / 70 / 90 Optional |

||||||

|

HEPA filter material |

Glass fibre |

||||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||||

|

Operating temperature |

10~40℃ |

||||||

|

Structure type |

Split type / Integrated |

||||||

|

Installation mode |

Horizontal / Vertical |

||||||

7.FFU parameters(3 speed room side replacement type ):

|

Model |

3 speed room side replacement typeFFU |

||||||

|

FFU dimension (mm) |

600X400 |

700X400 |

575X575 |

1175X575 |

1350X400 |

1470X400 |

Other(其他) |

|

FFU material |

Powder coated |

||||||

|

Fan |

AC |

||||||

|

Input |

220-230ACV/50HZ/1P |

||||||

|

Speed (m/s) |

0.45-1.0m/s Adjustable |

||||||

|

Control type |

Manual / RS485 |

||||||

|

HEPA Height (mm) |

50 / 70 / 90 Optional |

||||||

|

HEPA filter material |

Glass fibre |

||||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||||

|

Operating temperature |

10~40℃ |

||||||

|

Structure type |

Integrated |

||||||

|

Installation mode |

Horizontal / Vertical |

||||||

8.FFU parameters(EC energy saving type EC节能型):

|

Model |

EC energy saving type FFU |

||||||

|

FFU dimension (mm) |

600X400 |

700X400 |

575X575 |

1175X575 |

875X575 |

1010X610 |

Other(其他) |

|

FFU material |

Powder coated |

||||||

|

Fan |

EC |

||||||

|

Input |

220-230ACV/50HZ/1P |

||||||

|

Speed (m/s) |

0.45-1.0m/s Adjustable |

||||||

|

Control type |

RS485 |

||||||

|

HEPA Height (mm) |

50 / 70 / 90 Optional |

||||||

|

HEPA filter material |

Glass fibre |

||||||

|

HEPA efficiency |

H13 / H14 /U15 |

||||||

|

Operating temperature |

10~40℃ |

||||||

|

Structure type |

Integrated |

||||||

|

Installation mode |

Horizontal / Vertical |

||||||